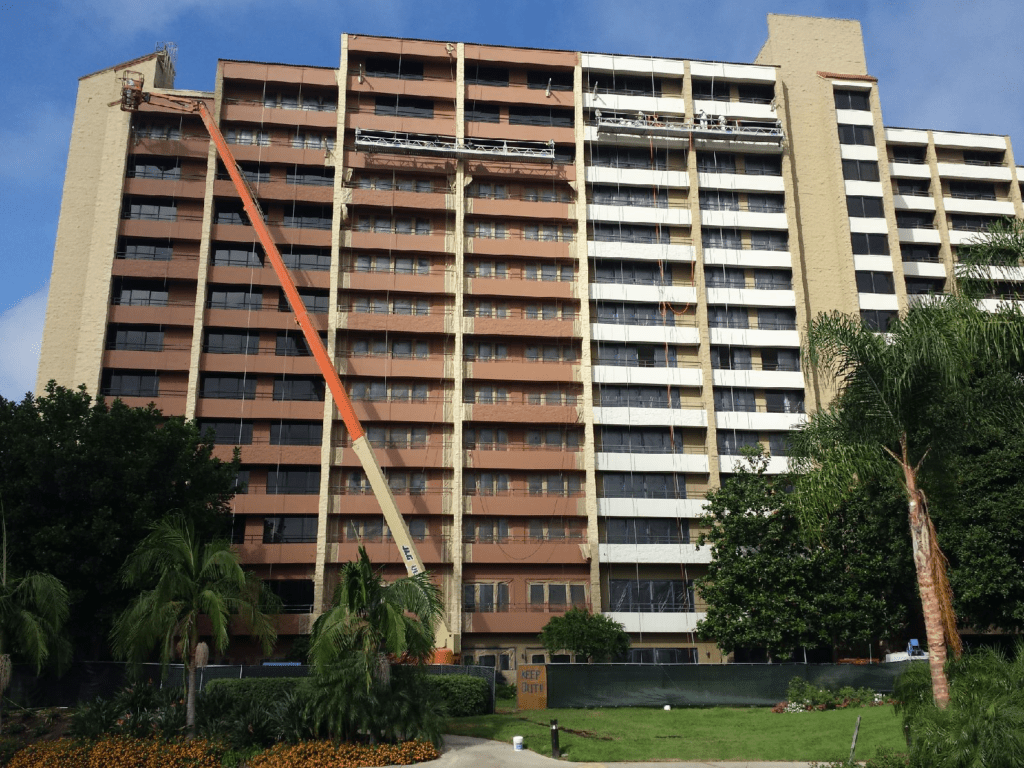

Towers at Laguna Woods Village, 311 Units |

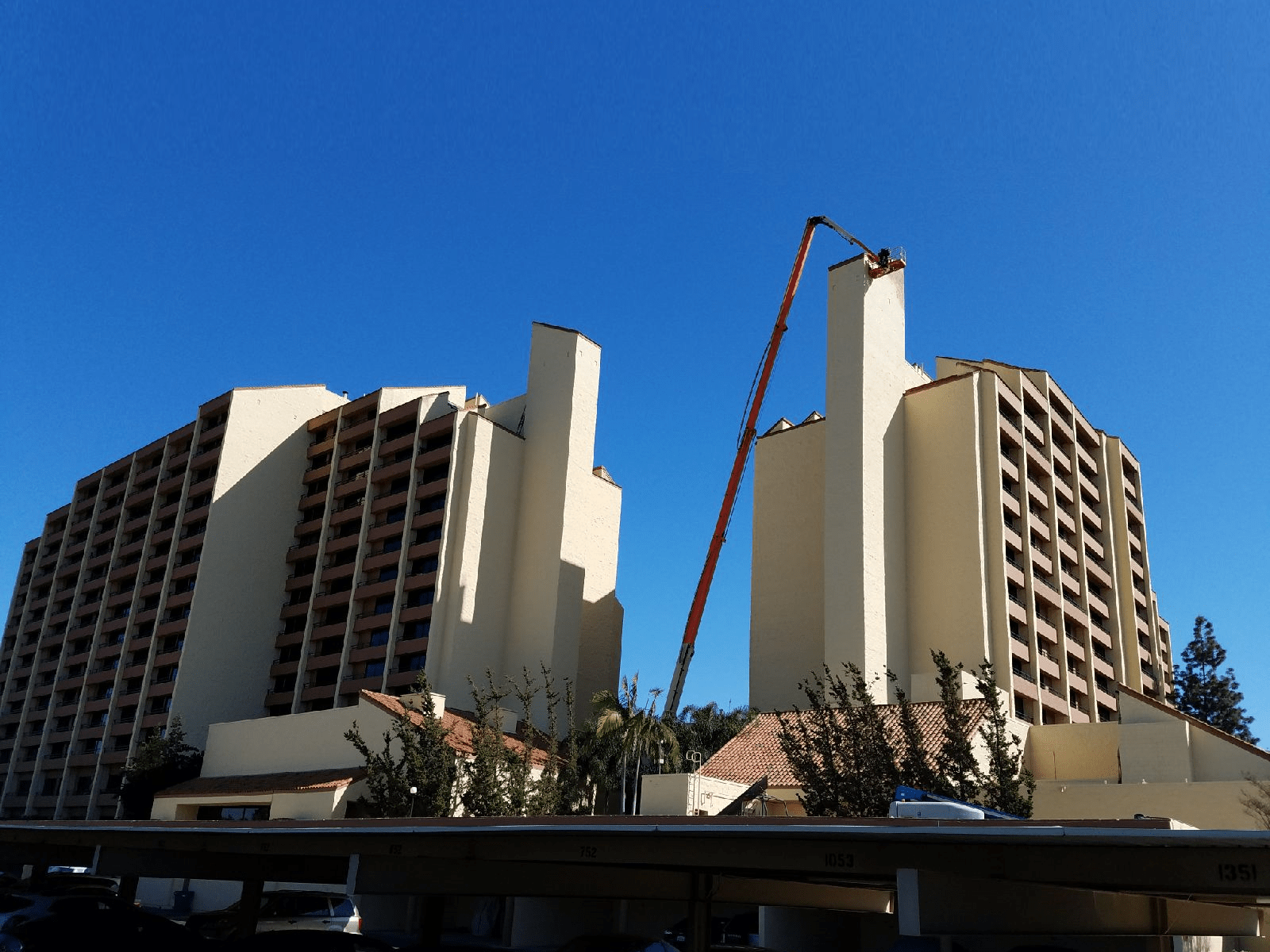

- Swing Stages + JLG 135 ft. Ultra Boom

- JLG Ultra Boom & banner

Built in 1974 These twin 14 story towers are built of solid grout split block masonry with walls that had been painted four times prior to our coating job. The aluminum windows, doors, and railings had peeling paint with corrosion showing. The masonry had some loss of inter-coat adhesion resulting in bubbling.

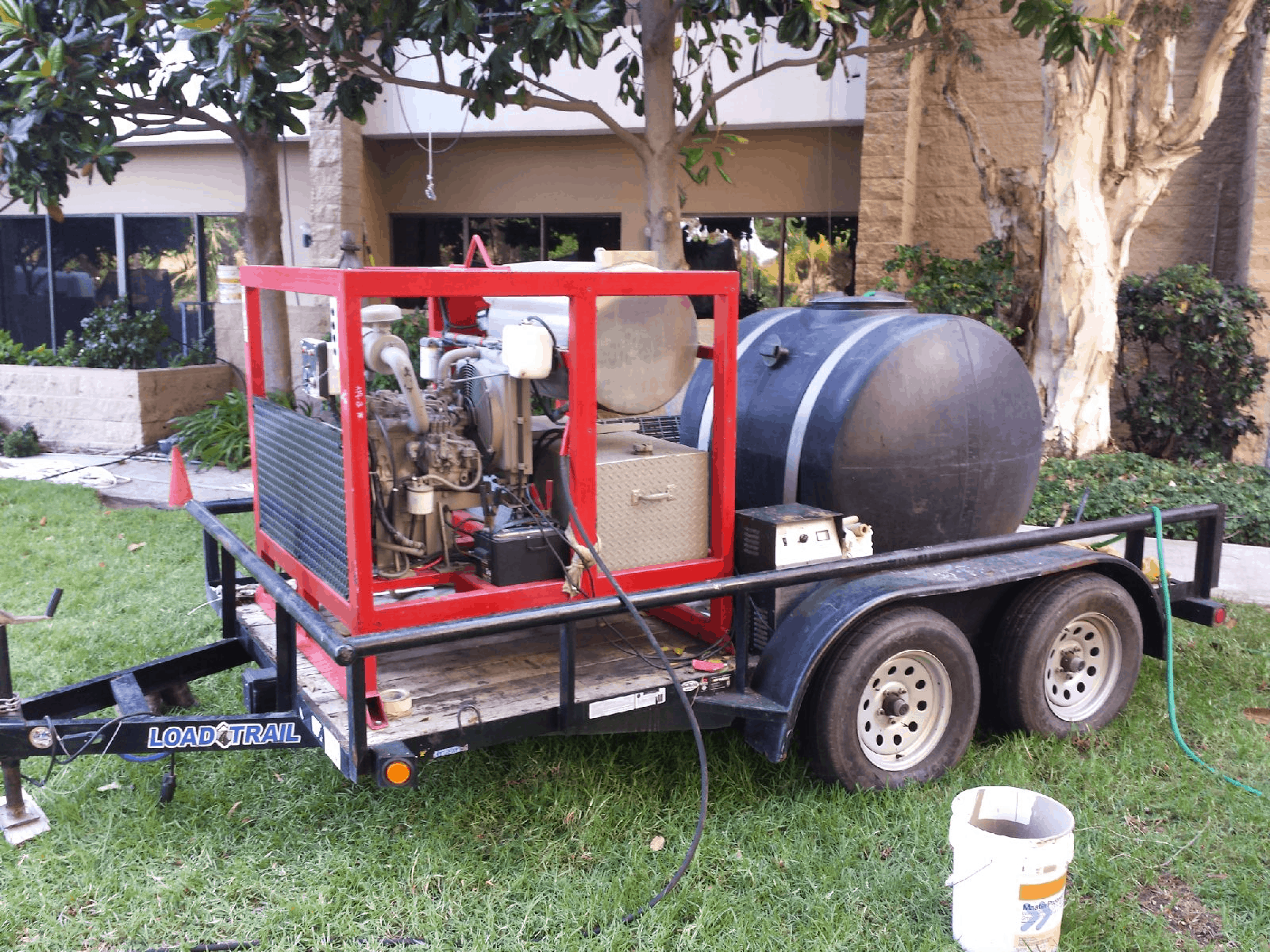

We removed the visible failing elastomeric coating on the masonry walls by using 5 gals per minute hot water high-pressure washing with 5,000 PSI and by using hand power tools.

- Diesel High powered pressure washer

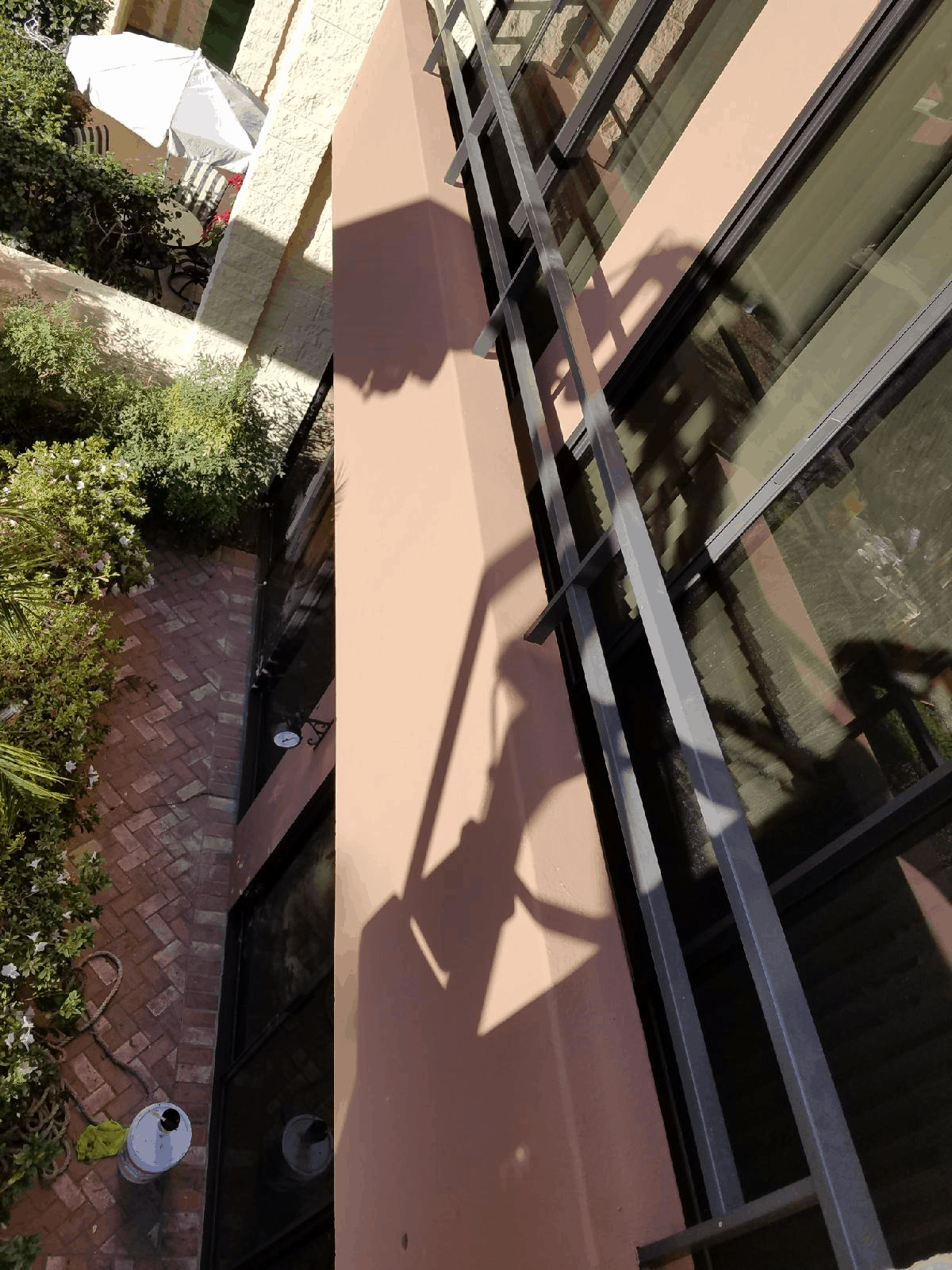

- Pressure washing

- Vapor Blasting – Dustless abrasive blasting method

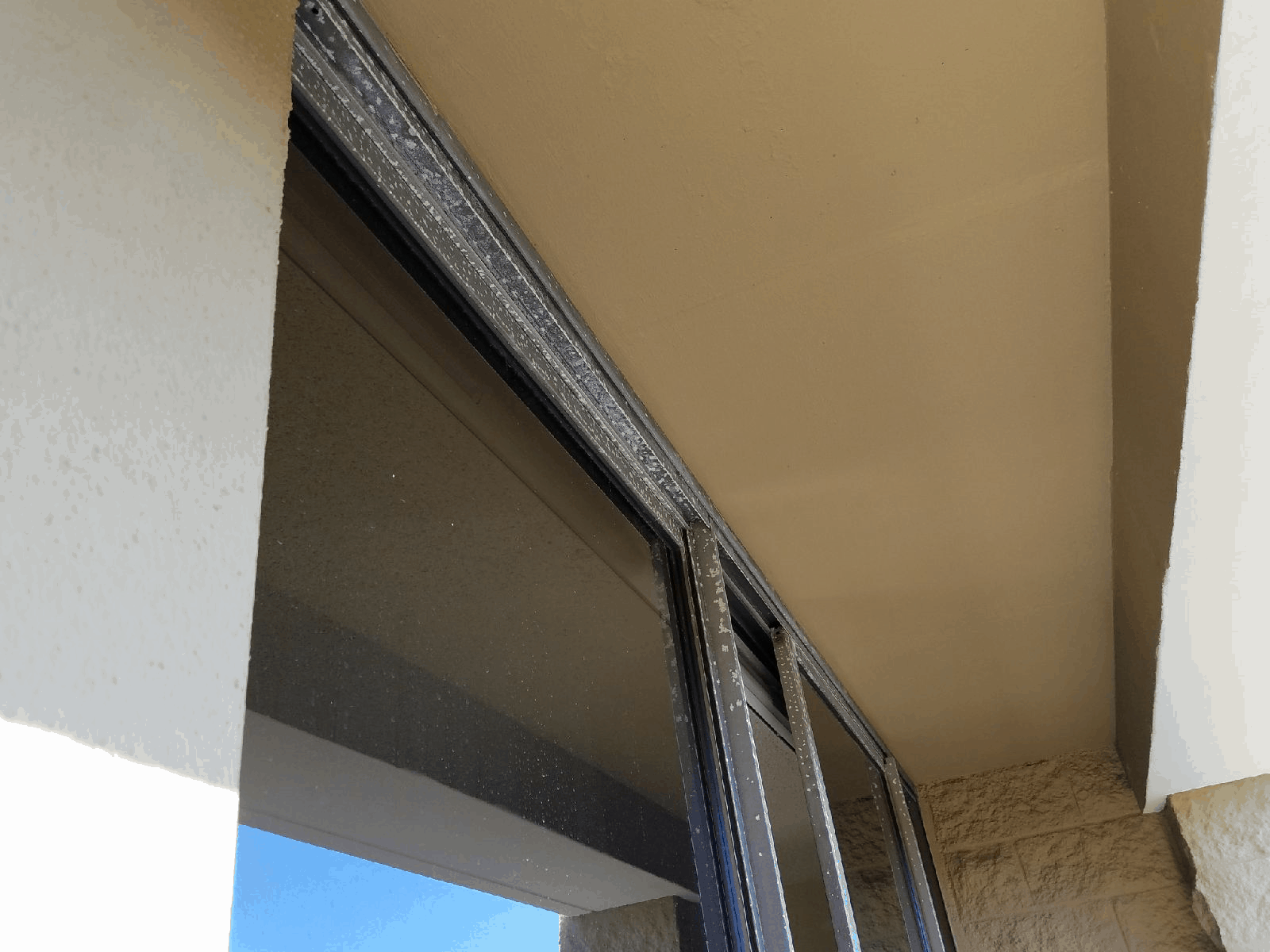

- Actual failed coating

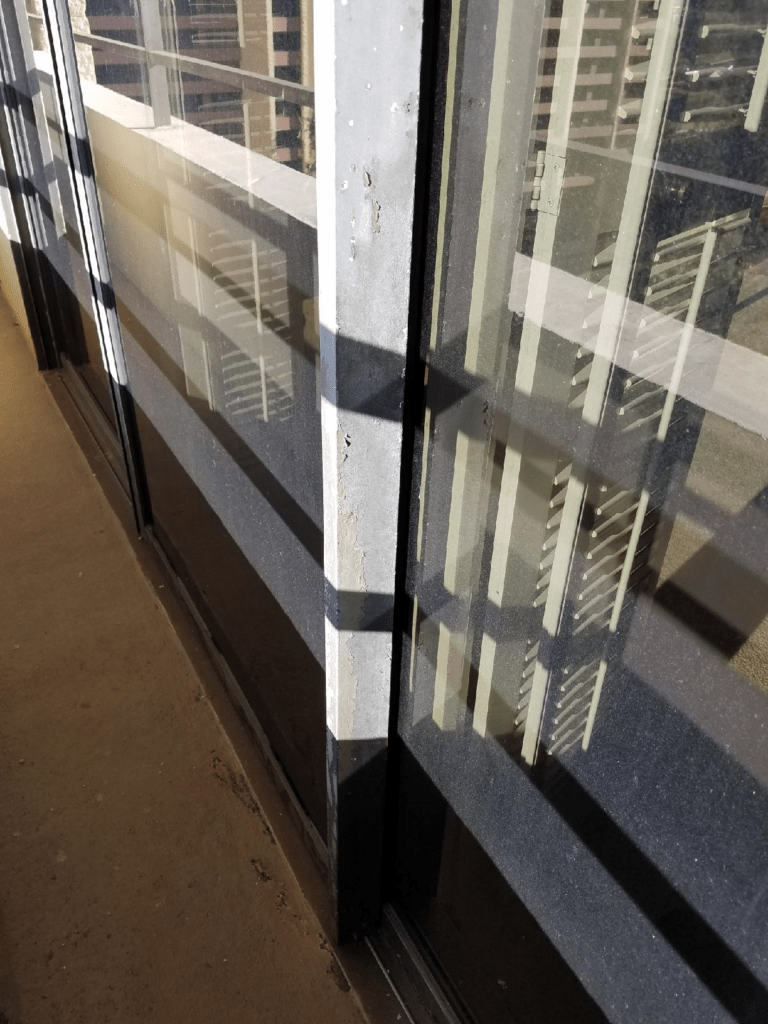

The aluminum rails, windows, and doors were prepared by hot water high-pressure washing, the remaining old coatings were removed by using hand-held orbital sanding machines with 2-inch and 5-inch discs. The metal handrails were primed and finished with high-performance protective paint PPG PSX 700. All the aluminum windows and doors were restored by applying using high-quality fluoropolymer paint and finish coat, Enquire for details.

- Concrete repair company L.A.

- PSX 700 High Performance protective coating

- Finished rails

- We work rain or shine

- Pitted windows

- Swallow droppings

- Slider paint failure

- Corroded windows

- Entry doors

Parker painting crews worked non-stop, even in the rain to complete this project ahead of the allotted time schedule.

Twice we had to assist in the extermination of hybrid Africanized bee colonies at 165 feet above the ground. These hybrid bees were very aggressive they swarmed chased people stinging while attacking. We secured and caulked all the upper metal flashings to prevent swallows from nesting in the open flashing gap. The crews had to wait for an owl family to hatch eggs and rear its young on one upper balcony, see photo.

- Africanized Bee Removal

- Mother Owl and babies

- Many gophers died to feed these baby owls

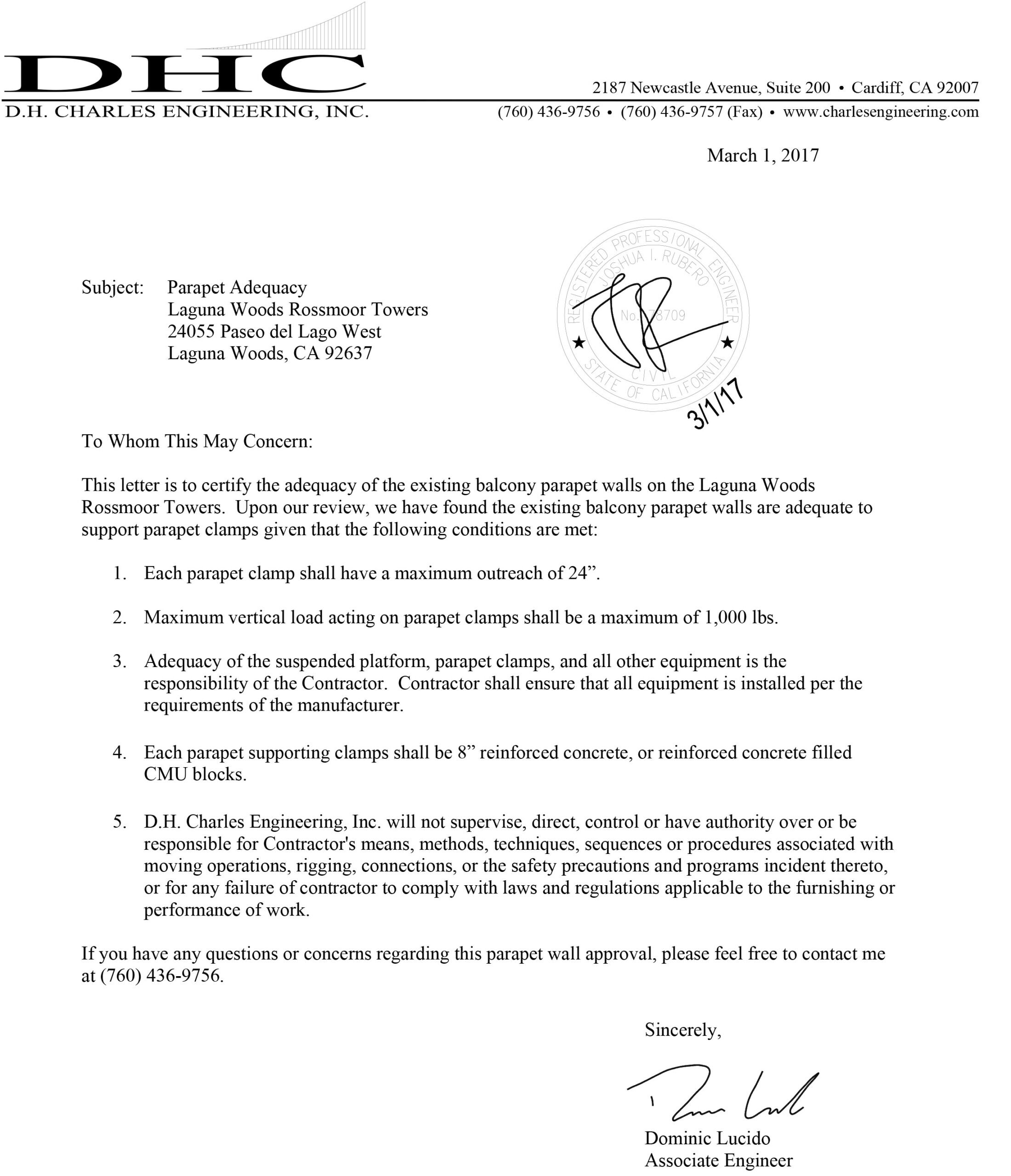

We performed x-rays of the concrete balcony walls and decks to show the reinforcement steel bar placement in the concrete to ensure the safe use of 45,000 lb heavy equipment and parapet clamps. Boom Lift tires were fitted with protective covers to prevent black tire marks on the deck concrete which was also covered with large tarping.

- x ray identifying the steel rebar in decks

- Rebar Core

- Marking rebar in wall x-rays

- Marking rebar in the wall after x-rays

- x ray marking for steel rebar in walls

- Engineers stamped calculations verifying safe use of staging

- Cars covered for overspray protection

-

JLG 185ft Over The Top reach

Utilization of well-engineered equipment

Cars were completely covered with Visqueen to insure no paint overspray on any cars. The job was executed systematically and inspected for quality during each phase of progress. By skillful workmanship along with careful ingenious manipulation of large boom lifts and swing stages, a safe very high-quality beautiful job was turned over to the association.

- Covered deck – Ultra Boom booties

- Pro Painter for difficult jobs

We specified and used PPG PSX 700 siloxane high-performance protective coating on all the railings.

OEM high-quality fluoropolymer paint and topcoat on all the window frames and aluminum doors.

BASF HB 200 Waterproof coating, BASF primer 100 on the masonry walls.

Sherwin-Williams H&C Acryla cool deck coating on the unit balcony decks.

Over 6,000 gallons of coating material were used on this project.

For exceptional quality, service and value, Contact us today.

Contact UsBelow are just a few photos of the hundreds of free hats given by Jim Parker to the beautiful and interesting residents of the Towers at Laguna Woods during our commercial painting job.

- Free hat giveaway at The Towers

- more free hats and happy residents

- Even more free hat giveaways