Read some of our Case Studies…

Painting the rocket at SpaceX headquarters | Hawthorne California

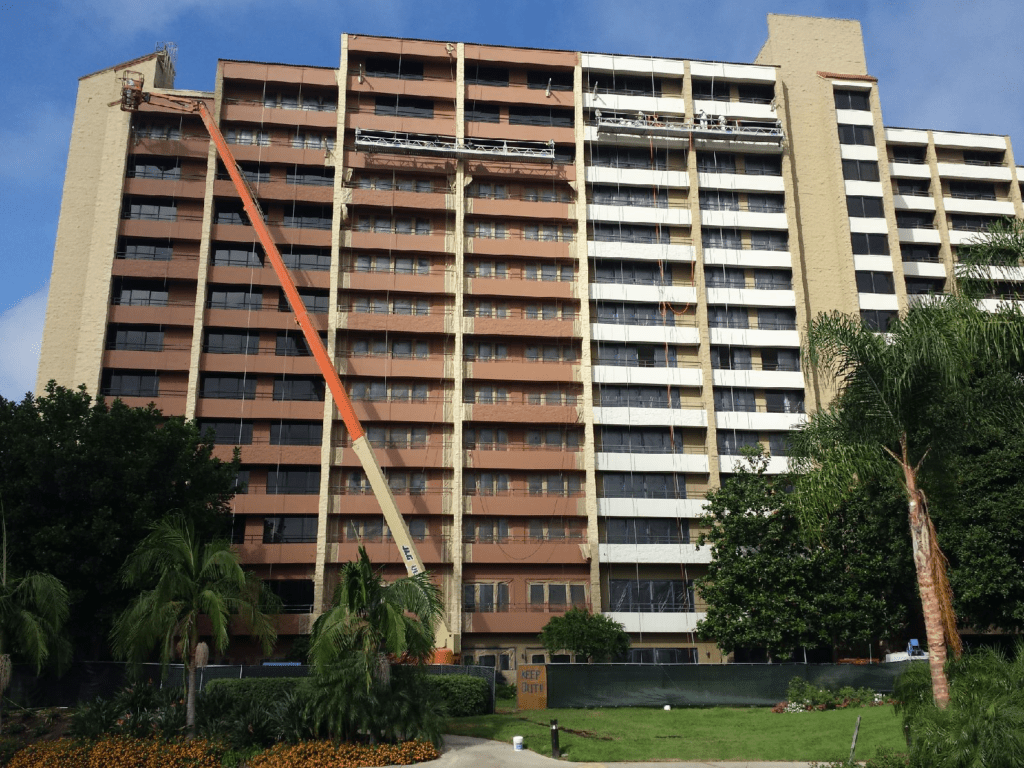

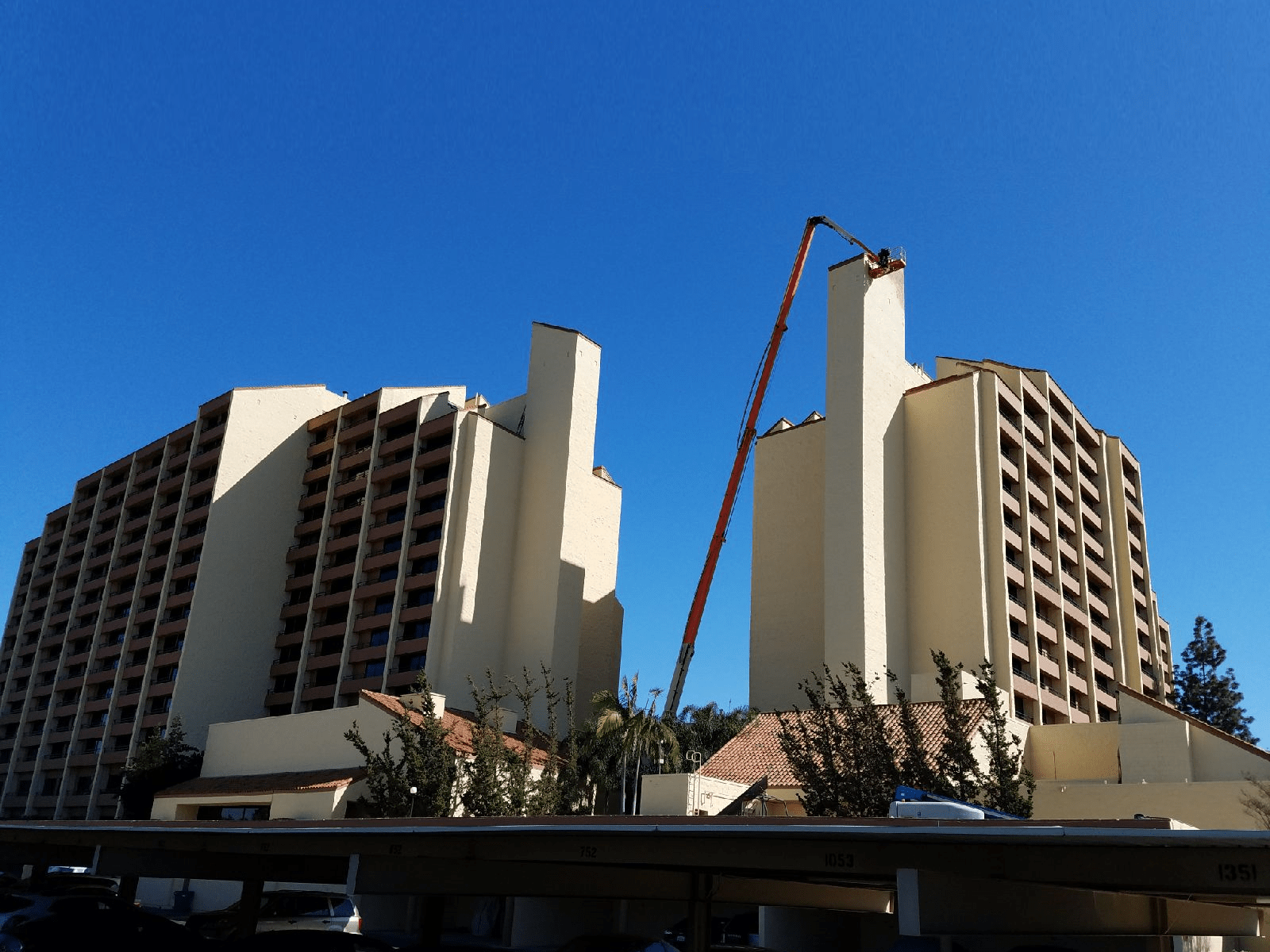

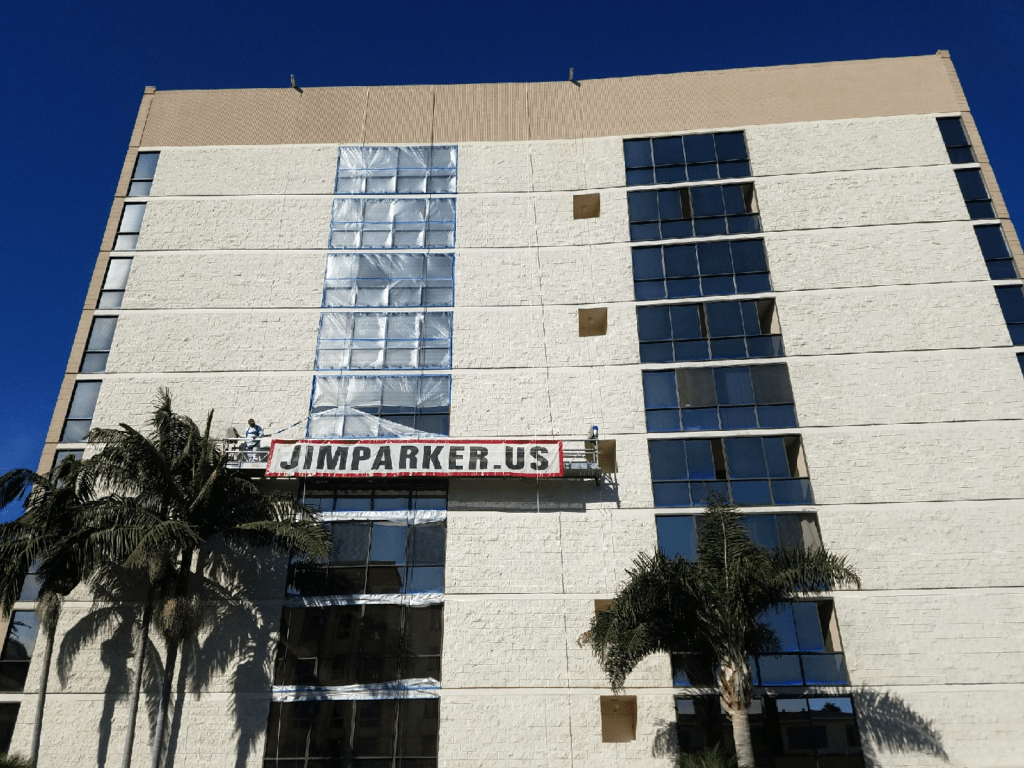

Towers at Laguna Woods Village, 311 Units |

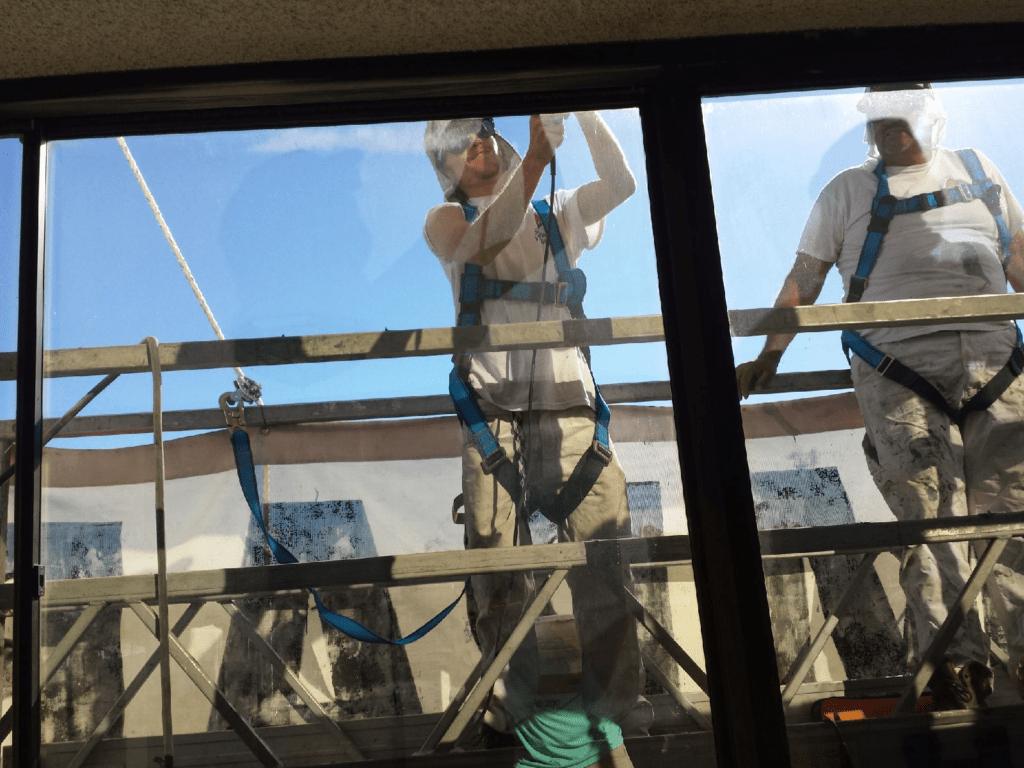

- Swing Stages + JLG 135 ft. Ultra Boom

- JLG Ultra Boom & banner

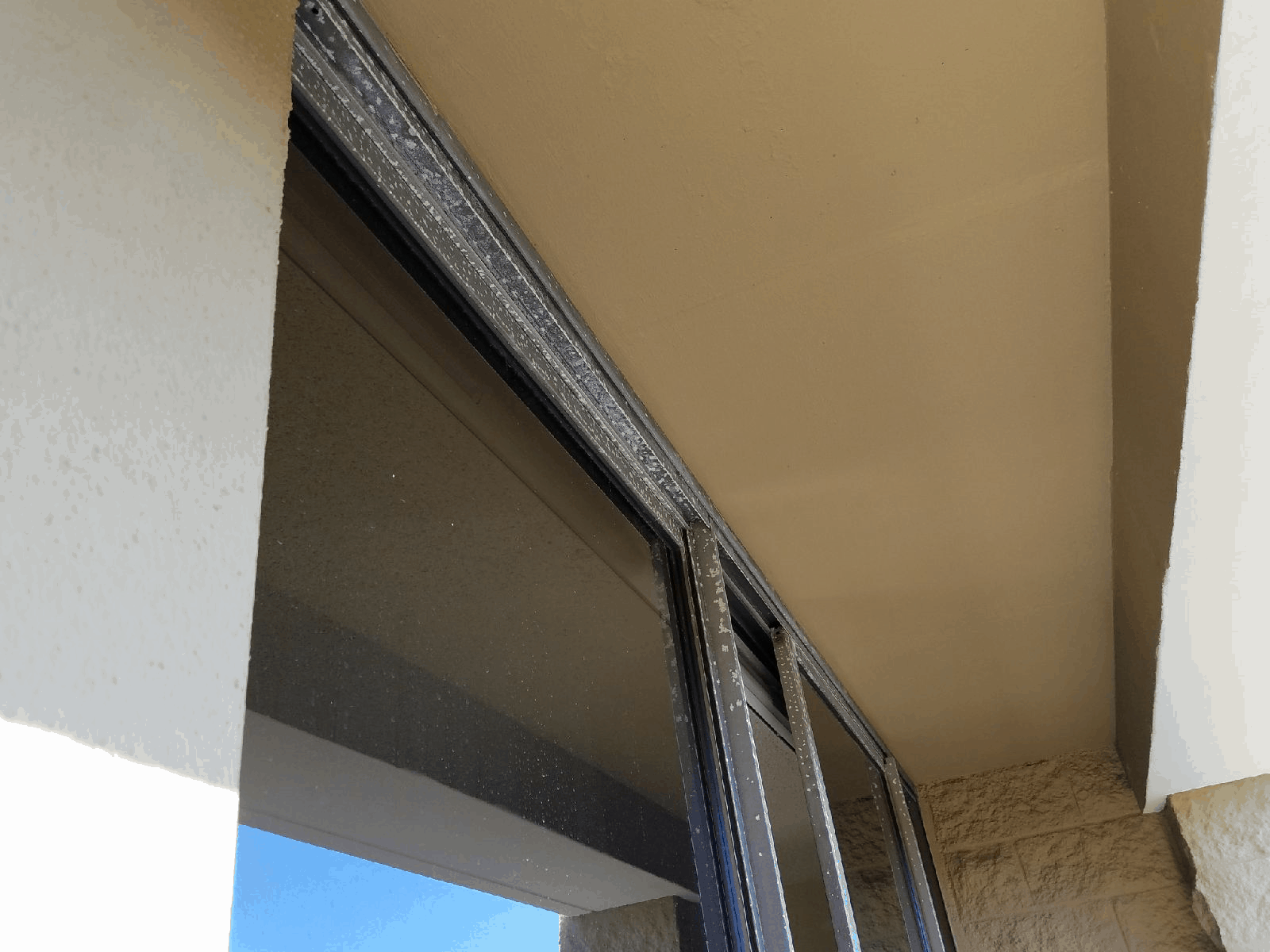

Built in 1974 These twin 14 story towers are built of solid grout split block masonry with walls that had been painted four times prior to our coating job. The aluminum windows, doors, and railings had peeling paint with corrosion showing. The masonry had some loss of inter-coat adhesion resulting in bubbling.

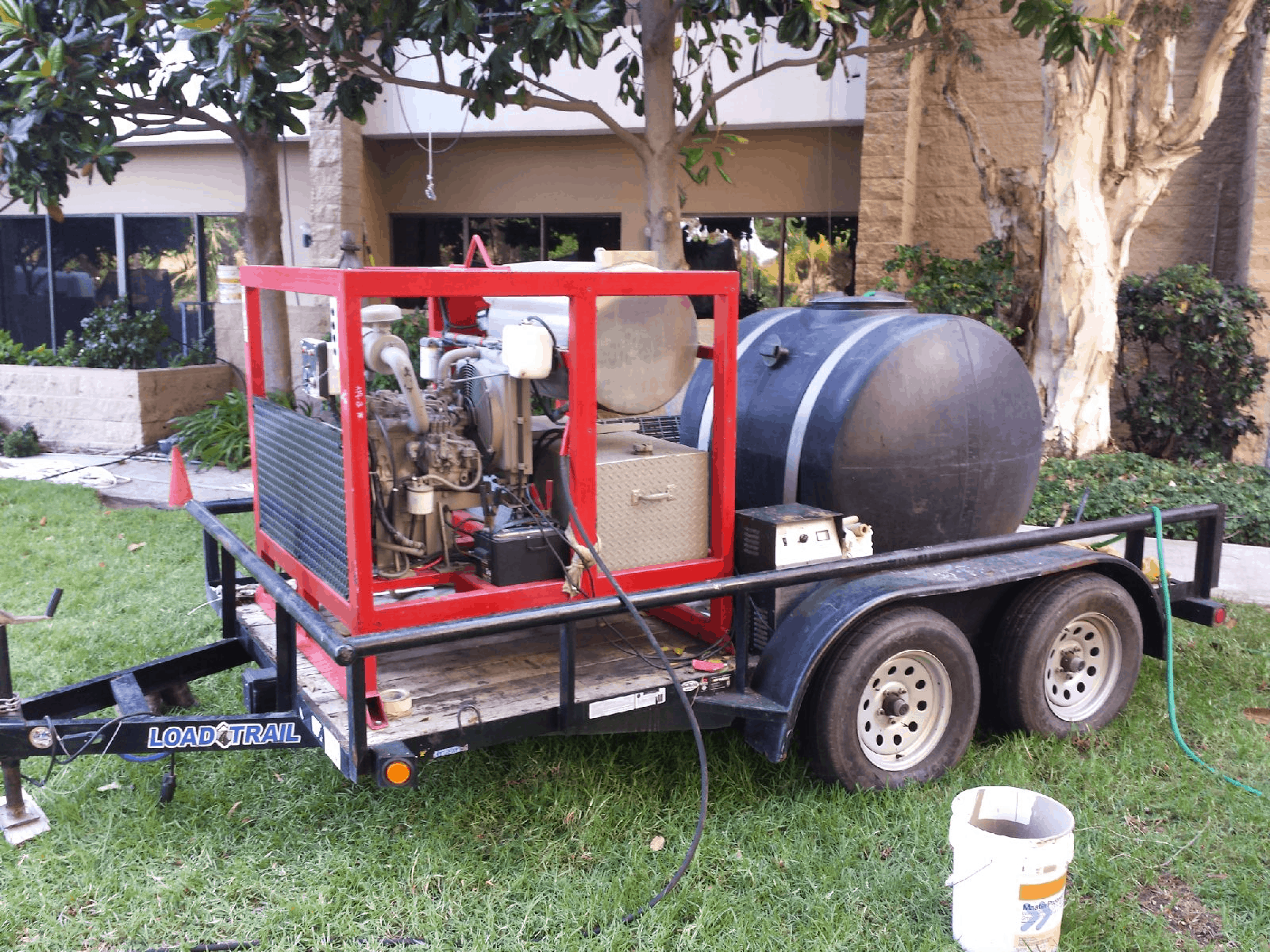

We removed the visible failing elastomeric coating on the masonry walls by hot water pressure washing with 5000 PSI and by using hand power tools.

- Diesel High powered pressure washer

- Pressure washing

- Vapor Blasting – Dustless abrasive blasting method

- Actual failed old coating

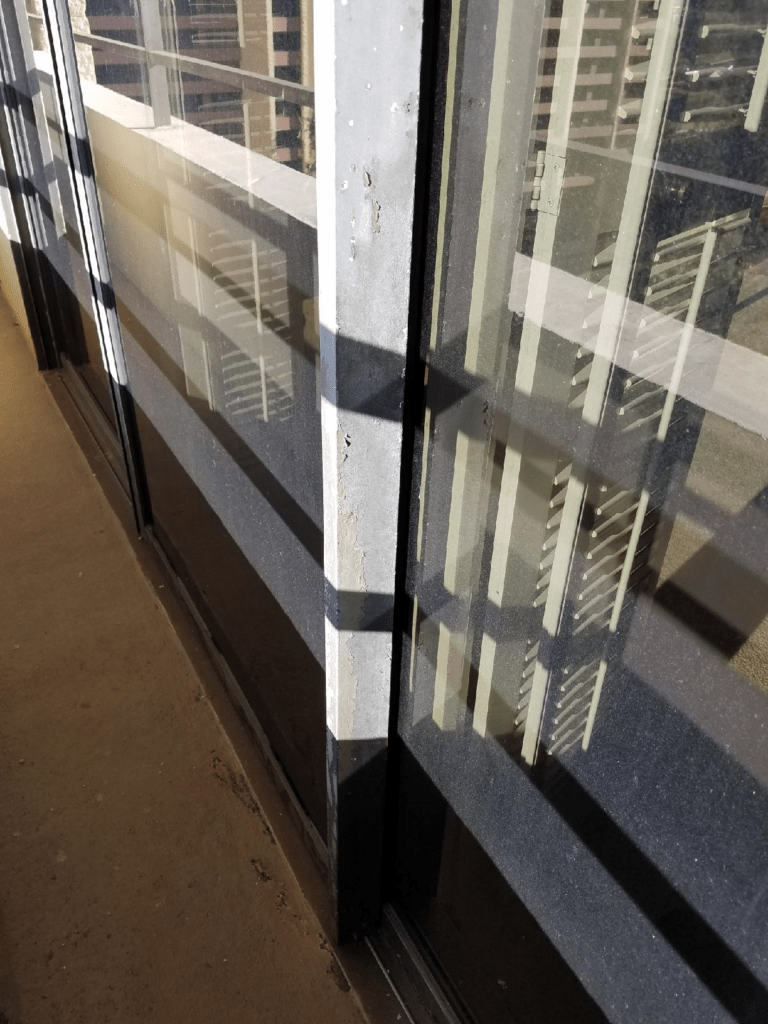

The aluminum rails, windows, and doors were prepared by hot water high-pressure washing, the remaining old coatings were removed by using hand-held orbital sanding machines with 2 inch and 5-inch discs. The metal handrails were primed and finished with high-performance protective coating PPG PSX 700. All the aluminum windows and doors were restored by applying using high-quality fluoropolymer paint and finish coat. Enquire for details.

- Concrete repair company L.A.

- PSX 700 High Performance protective coating

- Finished rails

- We work rain or shine

- Pitted windows

- Swallow droppings

- Slider paint failure

- Corroded windows

- Entry doors

Parker crews worked non-stop, even in the rain to complete this project ahead of the allotted time schedule. Twice we had to assist in the extermination of hybrid Africanized bee colonies at 165 feet above the ground. These hybrid bees were very aggressive they swarmed chased people stinging while attacking. We secured and caulked all the upper metal flashings to prevent swallows from nesting in the open flashing gap. The crews had to wait for an owl family to hatch eggs and rear its young on one upper balcony, see photo.

- Africanized Bee Removal

- Mother Owl and babies

- Many gophers died to feed these baby owls

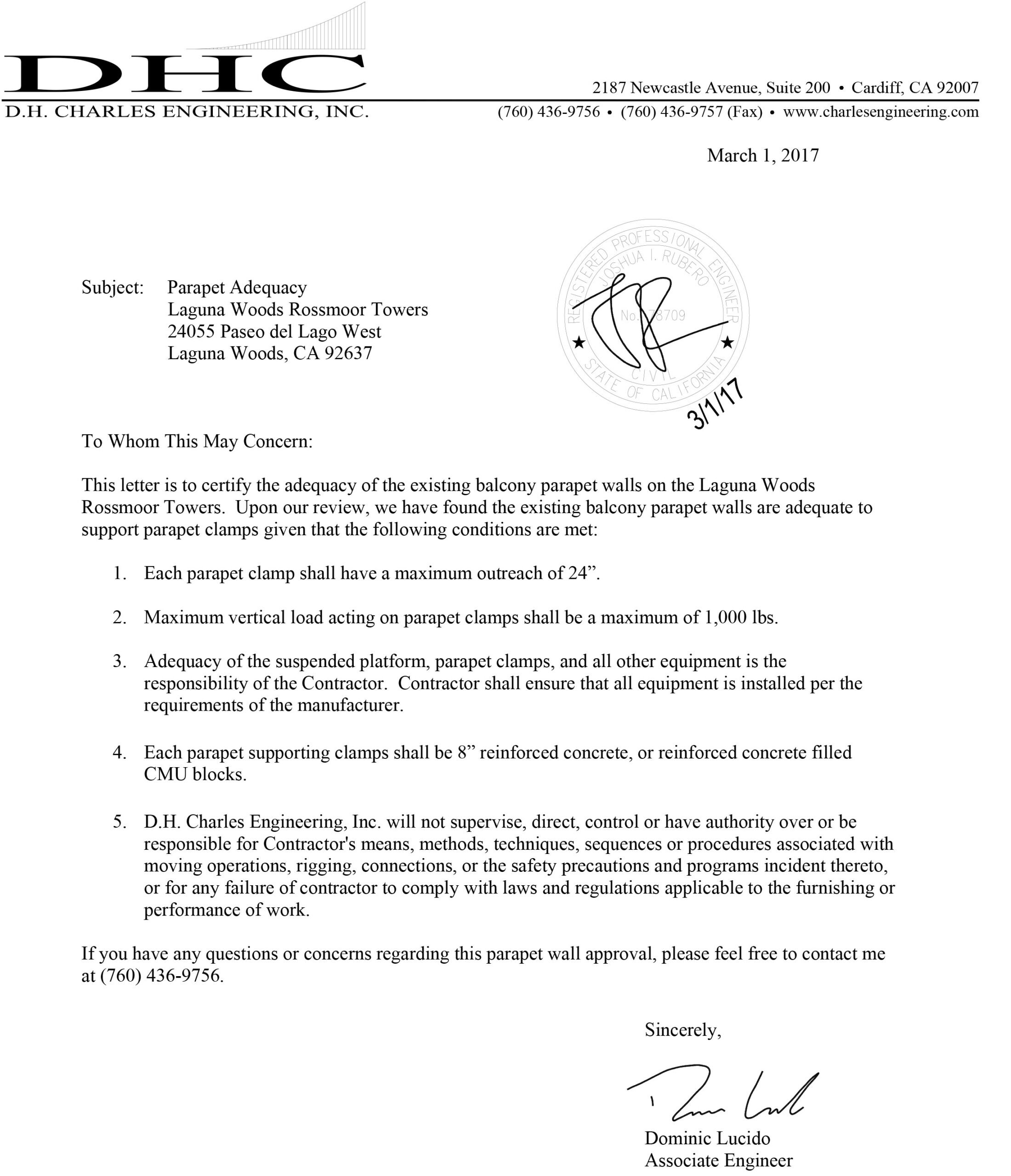

We performed x-rays of the concrete balcony walls and decks to show the reinforcement steel bar placement in the concrete to ensure the safe use of 45,000 lb heavy equipment and parapet clamps. Boom Lift tires were fitted with protective covers to prevent black tire marks on the deck concrete which was also covered with large tarps.

- x ray identifying the steel rebar in decks

- Rebar Core

- Marking rebar in wall x-rays

- Marking rebar in the wall after x-rays

- x ray marking for steel rebar in walls

- Engineers stamped calculations verifying safe use of staging

- Cars covered for overspray protection

-

JLG 185ft Over The Top reach

Utilization of well-engineered equipment

Cars were completely covered with Visqueen to insure no paint overspray on any cars. The job was executed systematically and inspected for quality during each phase of progress. By skillful workmanship along with careful ingenious manipulation of large boom lifts and swing stages a safe very high-quality beautiful job was turned over to the association.

- Covered deck – Ultra Boom booties

- Pro Painter for difficult jobs

We specified and used PPG PSX 700 siloxane high-performance protective coating on all the railings.

OEM high-quality fluoropolymer paint and topcoat on all the window frames and aluminum doors.

BASF HB 200 Waterproof coating, BASF primer 100 on the masonry walls.

Sherwin-Williams H&C Acryla cool deck coating on the unit balcony decks.

Over 6,000 gallons of coating material were used on this project.

For exceptional quality, service and value, Contact us today.

Contact UsBelow are just a few photos of the hundreds of free hats given by Jim Parker to the beautiful and interesting residents of the Towers at Laguna Woods during our commercial painting job.

- Free hat giveaway at The Towers

- more free hats and happy residents

- Even more free hat giveaways

The James Oviatt Building | 617 S Olive – Los Angeles, CA.

Los Angeles Historic-Cultural Monument #195, listed in the National Register of Historic Places.

- Concrete Spall repair – Windows masked

- Oviatt Building – Deteriorated windows

- Oviatt Building – Historic Painting

- Oviatt Building – Repaint crest

- Oviatt – Repaint multicolor crest

- Oviatt Building – Spall repair

- Oviatt Building – completed patching

- Oviatt- painting reference letter

This grand building opened in 1928 as the headquarters for the Alexander Oviatt men’s clothing company. Twelve stories with a beautiful neon clock tower it was built with poured concrete walls in Italian Romanesque design with classic ornate trim. It is a prime example of Reni Lalique glass.

Fifteen years prior to our contract was the last time this building was painted, we learned that the entire job was done at that time from window washers bosuns chairs repelling down the sides not giving the workmen a stable work platform. Consequently, this grand building did not get the proper care it deserved as evidenced by the extensive concrete spalling and neglected windows shown in the first two pictures above.

The owner contracted with Parker in 2011 to restore and waterproof the exterior walls and trim. The job involved but was not limited to rigging all the elevations for work access, identifying, removing all hollow or unsound concrete, excavating spalling and cracks, preparing exposed steel rebar, patching, priming, and applying a waterproof Elastomeric coating system that ended all water intrusion on the first attempt.

We repainted the beautiful multicolor Oviatt crest on the clock tower west wall. The street front elevation windows made of wood were in an extremely deteriorated state, with the wood cellulose exposed to the elements for years and very soft. Many had lost most of the glass glazing, after skillful preparation, our crews applied a high-quality low viscosity penetrating epoxy to restore the wood. After that we sanded, primed, re-glazed, and painted them bringing them back to their original beauty and color.

Truly a beautiful old building, view the pictures and owner signed reference letter of this very interesting coating job.

Contact Us

Central Plaza | 3440, 3450, 3460, 3470 Wilshire Blvd – Los Angeles, CA.

Within 72 hours Parker had a signed contract, placing manpower, material, and equipment on the job.

- Central Plaza Exterior Rehab

- LA High Rise Painting

- LA Commercial Painting

- Central Plaza Painting

- Painting Reference Letter

- Waterproofing Warranty

Central Plaza is a constant use high rise commercial office complex consisting of four twelve-story buildings having retail stores and restaurants on the ground level. Built in 1952, in the early 1990s, it was in need of an extensive exterior upgrade. As is the case on many large projects, after taking bids from numerous contractors the upgrade project was put on hold due to high cost, in excess of 1.3 million dollars. This project was shelved for close to two years until Jim Parker met with the owners’ construction manager. Within 72 hours Parker had a signed contract, placing manpower, material, and equipment on the job.

Parker completed the project in minimal time, doing extra work painting the parking structure interior, line striping, painting stairwells, resealing the 3470 building windows, and providing a 20-year waterproof warranty. On Jan 17, 1994, the massive Northridge Earthquake struck causing hundreds of annealed glass windows to break in these buildings, fortunately, most were tinted with inside film, saving glass shards from raining down. Again Jim Parkers’ company-owned access equipment and crew saved the owner money and time by rapidly installing over $250,000 worth of new window glass at considerable cost savings.

All of the masonry curtain walls and ground-level facia of these buildings were prepared, filled, a primus cement base coat was trowel-applied, then a worm finishes synthetic plaster was applied, lastly, it was coated with an elastomeric coating. All un-anodized window mullions were painted. All the exterior surfaces of all four buildings were coated and painted by Parker in 1993, as of February 2013 they have not been repainted. Twenty years of quality high use commercial service life with no coating failure. In fact, the job looks new. We can do the same for your project.

For exceptional quality, service and value, Contact us today.

Contact Us

Country Club Manor | 316 N Rosmoore – Los Angeles, CA.

Parkers’ workmen accomplished the entire job without one personal interior item damaged or missing.

- HOA window painting

- HOA painting reference

- Country Club Manor Painting

Built in 1926 the ” Country Club Manor” is a six-story concrete poured-in-place architectural gem, just two blocks from Larchmont Village it was converted to high end condominiums in the 90s, by 2005 its’ expensive dual-pane mahogany windows were in need of complete restoration/refinishing. The OEM factory clear finish was failing to the point that many wood surfaces were totally exposed to the weather and had developed the dead gray, driftwood appearance.

The management company and the condominium board searched in vain to find a qualified Los Angeles painting contractor to do this challenging project within their budget until Jim Parker was referred. After completing a beautiful window sample Parker was given the contract. Parker crews did extra work removing and re-installing all of the black iron safety railings, preparing and spray painting them under containment on site. Parker also re-coated the interior windows of many of the units. Due to the complete sanding, striping, re-staining work, every single unit needed to be fully covered inside for protection.

Parker actually finished the work in less time than the allotted schedule. Completed in 2007 the beautiful mahogany windows now have a thicker catalyzed two-component urethane clear finish that is more durable than the factory finish due to the cross-linking of the molecules in the A and B components the finish coat is extremely tight, tough, and durable with a feel and service life similar to quality OEM automotive finishes. The coating used is free of harmful solvents, it is water-based, environmentally friendly, GREEN.

Contact us today for quality wood restoration and longer-lasting wood finishes.

Contact Us

Ocean Plaza HOA | 531 Esplanade – Redondo Beach, CA.

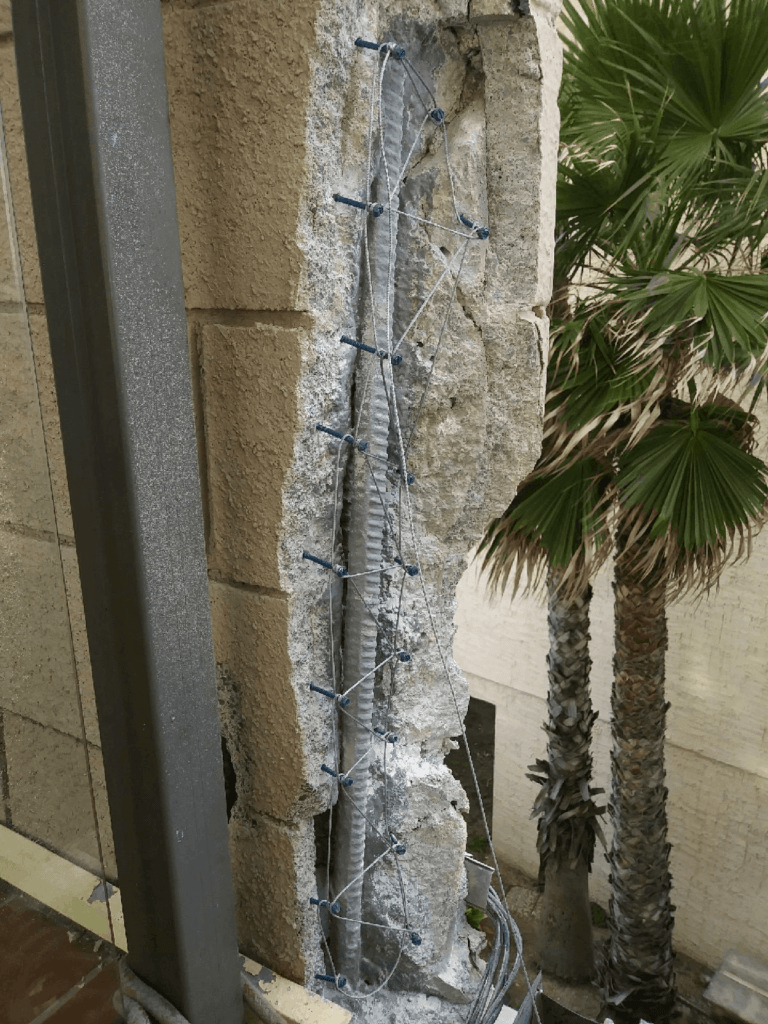

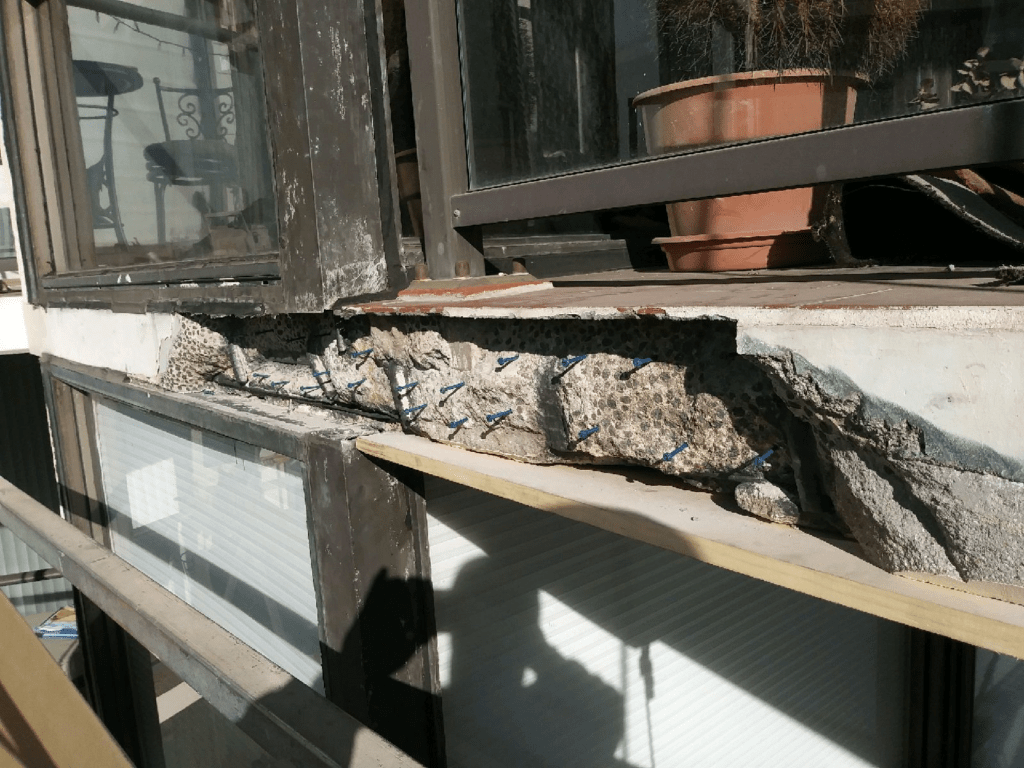

Concrete buildings on the oceanfront are subject to salt air, chlorides from saltwater waves breaking, and onshore winds. This severe adverse condition causes the chlorides to penetrate cracks in the concrete. If it reaches the steel reinforcement rust is inevitable so over time the steel expands to over eight times its original volume causing deterioration of the concrete and the rebar reinforcement. The concrete breaks away, called spalling, causing the dangerous condition below along with compromising the building itself.

- HOA complete exterior rehab

- Damaged concrete repair

- Damaged concrete repair

- Concrete Restoration

- Concrete Restoration

- High Rise Concrete Restoration

- Concrete spall repair

- Repaired deck

- Painting crew prepping windows

- masked windows for painting

We employ expert concrete building repair methods by using high-quality repair materials and workmanship. We excavate the spalling, remove all rust, apply a protective coating to the cleaned steel rebar, perform a solid patch to restore the concrete to better than the original quality. On this project on the west elevation we removed all the old foam backer rod and all the existing caulking, cleaned all joints, installed a new backer rod, re-caulked with all new BASF 150 urethane caulking material, after curing we masked all the windows, high pressure washed the entire wall, full primed all the concrete with BASF 100 primer, then applied two coats of BASF HB 200 waterproofing coating in two separate colors giving the building a beautiful new look making it waterproof once again.

Jim Parker also does the epoxy injection of concrete buildings with low viscosity high strength epoxy to fill cracks as a part of complete building restoration.

Contact Us

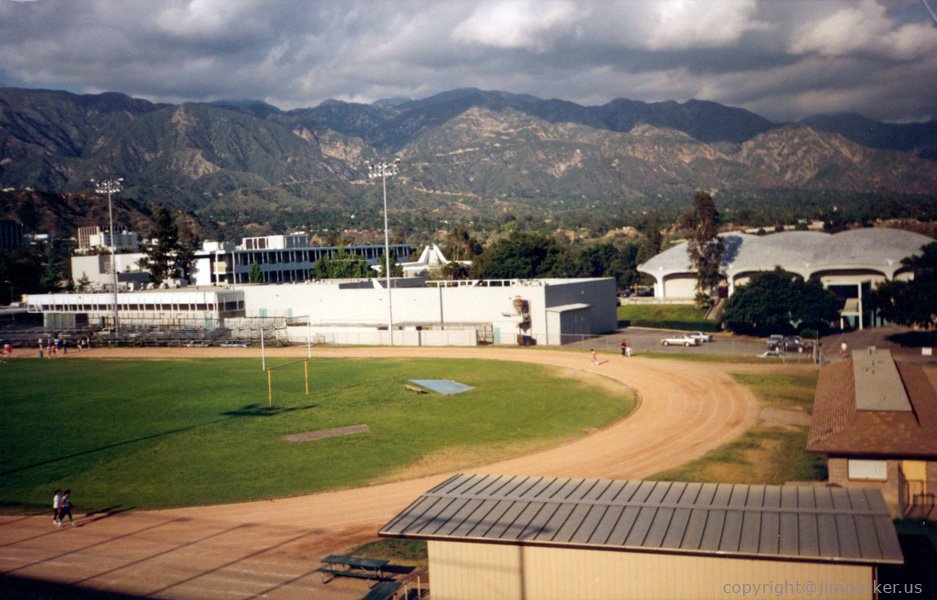

La Canada High School | 4463 Oak Grove Dr. La Canada, Ca. 91011

Parker offered to give the school board three years to pay for the job. The school board agreed.

- Painting La Canada High School

- Exterior Painting La Canada High

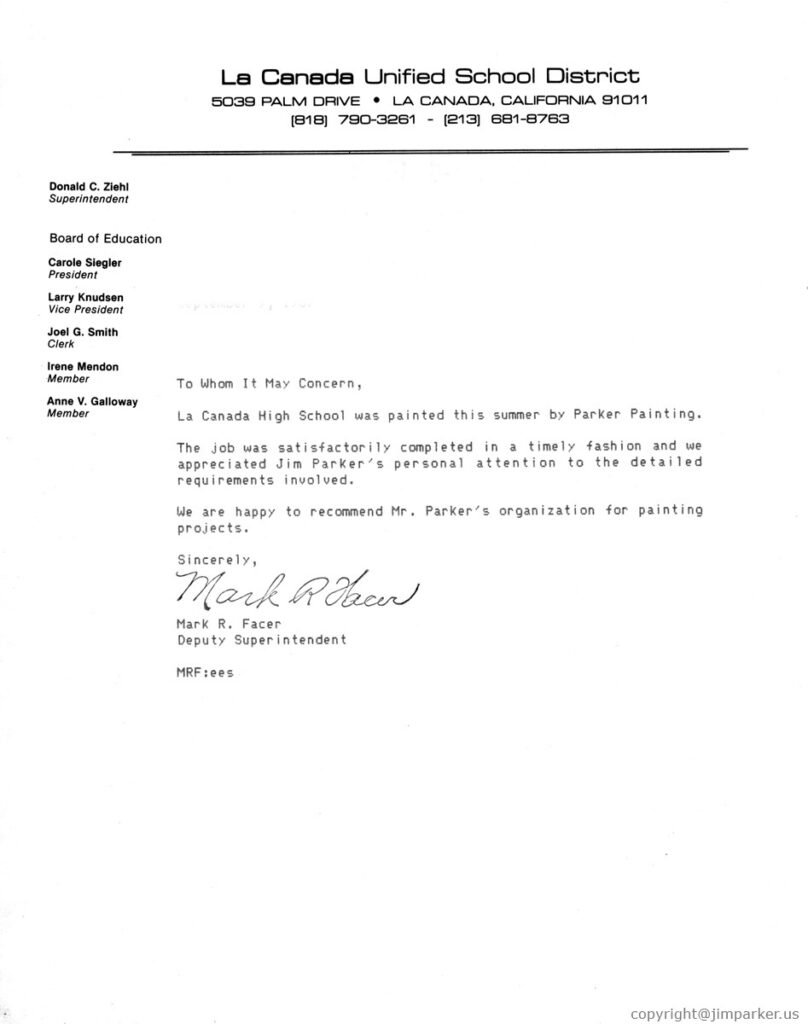

- Painting Reference letter

In 1987 the La Canada School District took public bids for the complete exterior painting of the La Canada High School campus. This was a standard bid/contract package.

Parker was the lowest responsible bidder on the six-figure contract. After attempting to award the contract to a more local contractor at a higher bid price, which is not legal, the school board actually proposed doing the entire painting job with volunteer parent labor citing lack of money as the reason.

Jim Parker attended the school board meeting staying until 10:30 pm, Parker offered to give the school district three years to pay for the job. The school district agreed. Parker completed the entire job doing extra work in six weeks that summer vacation period earning the attached reference letter. The district paid for the job in three equal payments over a three-year period.

This averted the disastrous idea of using volunteer parent help to paint the entire high school campus exterior. The district got a great paint job, see reference letter.

We will work with you to solve any special painting needs including financing.

Contact Us

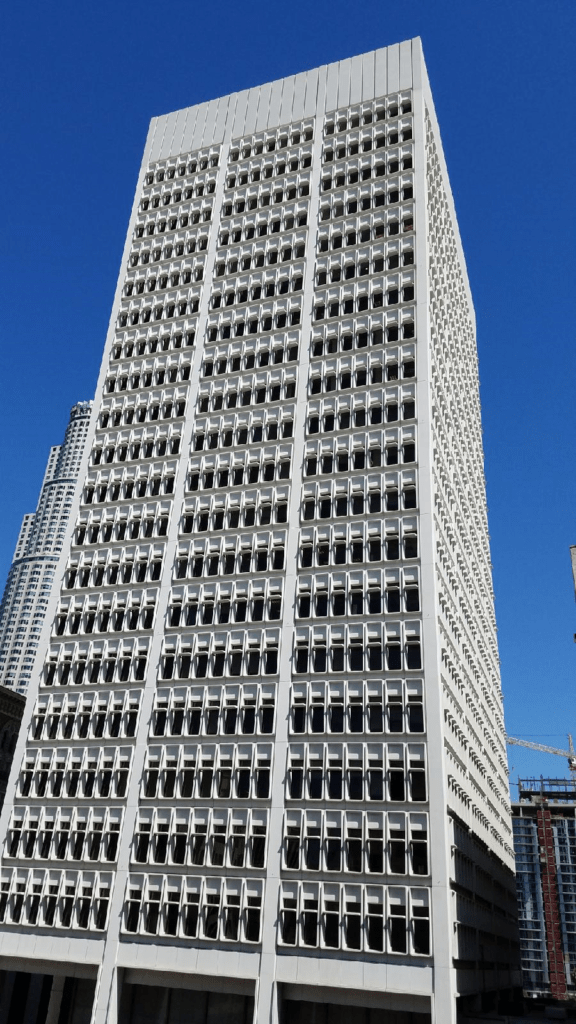

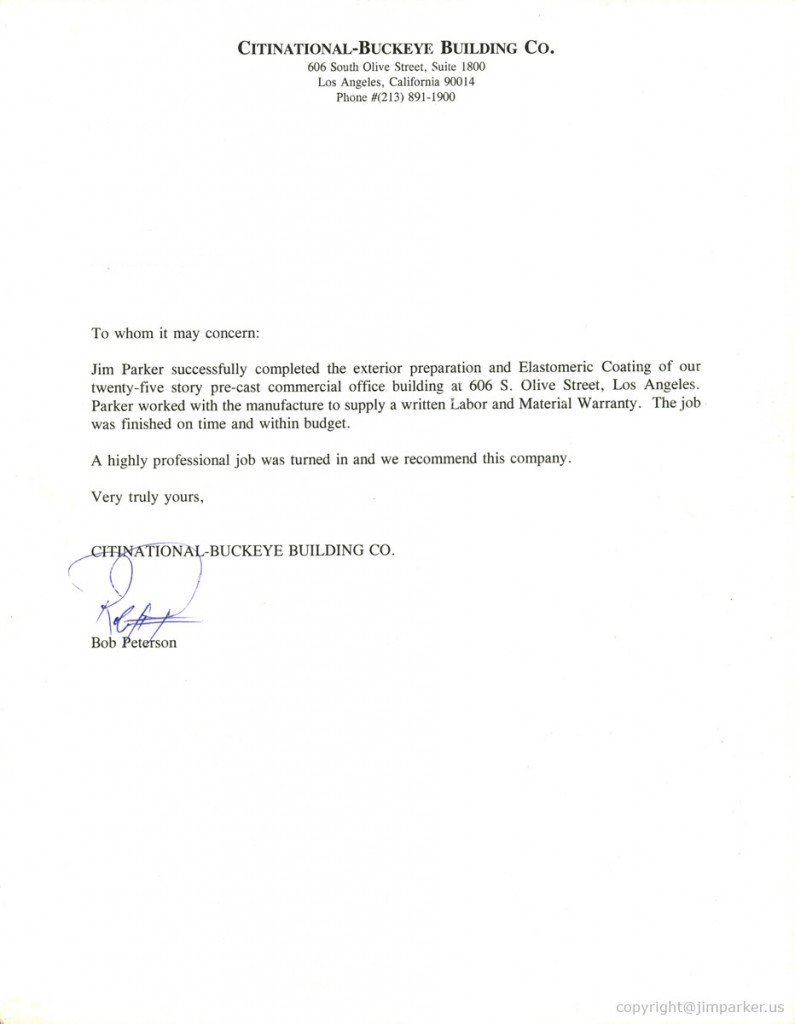

City National Bank | 606 S Olive Street, Los Angeles, CA 90014

We completed this concrete spall repair and waterproof coating job in early 1997 using our own scaffold equipment. Notice the complicated geometry of the cast concrete eyebrows, over four thousand gallons of Sika primer and coating, was applied.

- High Rise Spalling Repair

- LA spall repair and painting

The high-quality Elastomeric Coating used has far surpassed the ten-year warranty period by more than ten years showing no failure at all. The building facades have not been touched up or repainted, they have not even been washed or cleaned since 1997 to remove more than nineteen years of dirt build-up, stains, and harmful chlorides. It remains waterproof with no dis-bonded coating and stands tall as eminent proof of maintenance money well spent. We can do the same for your investment.

Contact us to find out more about the specialized extended Waterproof Coatings Labor and Material Warranties available.

Concrete Spall Repair and Elastomeric Waterproofing

- City National Bank building

- Historic Building Restoration

- Spall repair – 606 S Olive

- 606 Olive Street Los Angeles, Ca

For exceptional quality, service and value, Contact us today.

Contact Us